We are used to delivering high quality wire ropes with high strength and long life span. Our experienced workers have helped us to become one of the leading wire rope manufacturers and suppliers in India.

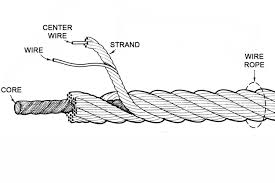

Wire rope is a type of cable made by twisting several strands of wire into a helix. It is widely used in industries such as construction, mining, oil and gas, and transportation due to its high strength, durability, and flexibility. Wire rope thimble manufacturers in India also play a key role by providing essential components that support the safe and effective use of wire ropes in these demanding sectors.

Wire rope is made from various materials and grades, each offering distinct characteristics and benefits. The material grade significantly influences the wire rope’s strength, durability, corrosion resistance, and flexibility. SVIBO Industries provides high-quality wire ropes engineered to meet specific performance requirements across diverse industrial applications.

The most common materials used in the manufacture of wire rope include stainless steel, carbon steel, and galvanized steel. Each material has different grades, with each grade designed for specific applications.

1.Stainless Steel SS wire rope

2.PVC Coated wire rope

3.Galvanized wire rope

4.Ungalvanized wire rope

Stainless Steel (SS) Wire Rope :

Stainless steel wire rope is a type of wire rope made from high-quality stainless steel. It is known for its excellent corrosion resistance, making it suitable for use in harsh environments, such as marine and offshore applications. Stainless steel wire rope is available in various grades, including 304, 316, and 316L.

PVC Coated wire rope :

We manufacture both galvanized or stainless steel wire ropes with a PVC, Nylon or Polypropylene coating to best suit your needs, the coatings are available in a wide range of colors to best suit your application.

PVC coating is used for general purpose .

Galvanized wire rope :

Galvanized wire rope is a steel write rope with a layer of zinc, which helps in preventing the ropes from corrosion and rusting. Mostly suitable for construction in wet places, these wire ropes prevent the deposition of dust in the inner steel.

Ungalvanized wire rope :

Ungalvanized wires are designed to be flexible with a good fatigue life. Ungalvanized Wires are extensively used in general industries, including crane ropes, winch ropes, hoist ropes, wire ropes and rigging applications.

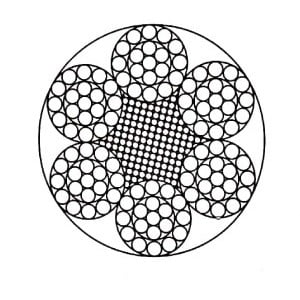

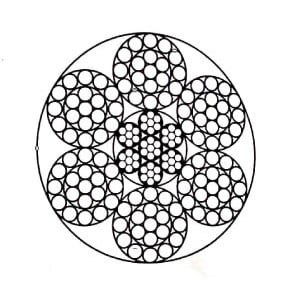

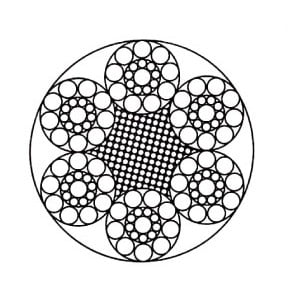

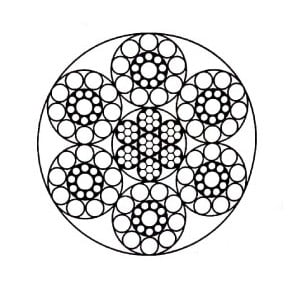

1

1  2

2  3

3  4

4  5

5  6

6  7

7