As one of the leading wire rope manufacturers and suppliers in India, SVIBO Industries offers a complete range of high-quality lifting and rigging solutions designed for safety, strength, and reliability. This guide will help you understand how to select the right equipment for your application and what factors to consider for optimal performance.

In industrial operations, safety and efficiency rely heavily on choosing the right lifting and rigging equipment. Whether you’re working in construction, manufacturing, shipping, or heavy engineering, the correct tools ensure smooth material handling and reduce the risk of accidents. From wire ropes to electric chain hoists and eye bolts, every component plays a vital role in lifting operations.

Understanding the Basics of Lifting and Rigging Equipment

Before selecting any tool or component, it’s essential to understand what lifting and rigging equipment includes.

- Lifting equipment: Devices used to move or raise loads, such as cranes, hoists, winches, and slings.

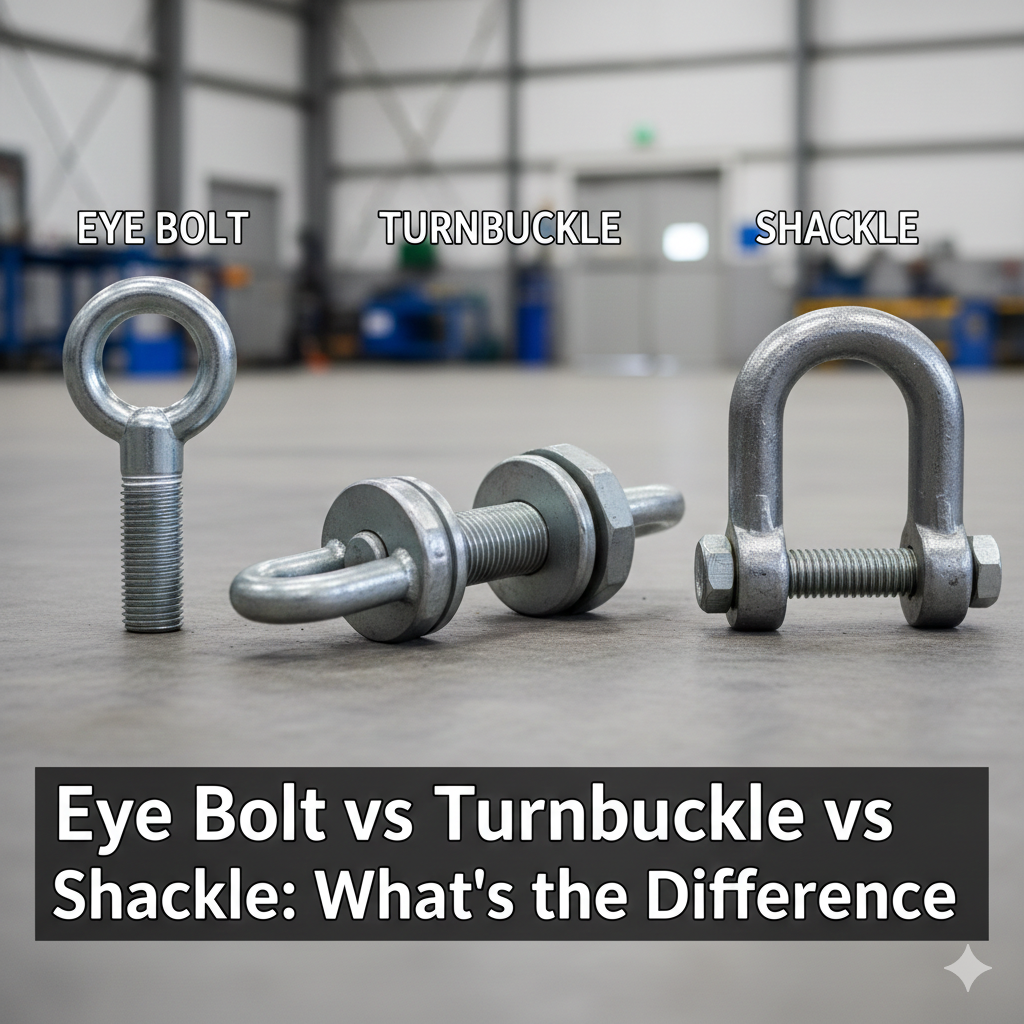

- Rigging equipment: Accessories that connect the lifting device to the load, like wire ropes, shackles, hooks, and eye bolts.

Together, these components ensure safe load handling, alignment, and balance during lifting operations. Each piece must meet specific load-bearing capacities and safety standards.

Assess Your Load Requirements

The first step in selecting any lifting or rigging gear is evaluating the type, weight, and nature of the load.

- Load weight and shape: Determine the maximum weight and consider how the load’s shape affects balance.

- Center of gravity: Ensure the lifting gear supports the load evenly to prevent tipping or swaying.

- Working environment: Consider temperature, moisture, and exposure to chemicals or corrosive agents.

- Frequency of use: For frequent lifting operations, choose durable materials and components designed for heavy-duty performance.

Example:

If your operation involves frequent vertical lifting, a durable electric chain hoist from a trusted manufacturer in India ensures consistent performance with minimal downtime.

Selecting the Right Type of Equipment

Different lifting applications require different tools. Here’s a quick overview of commonly used equipment and their functions.

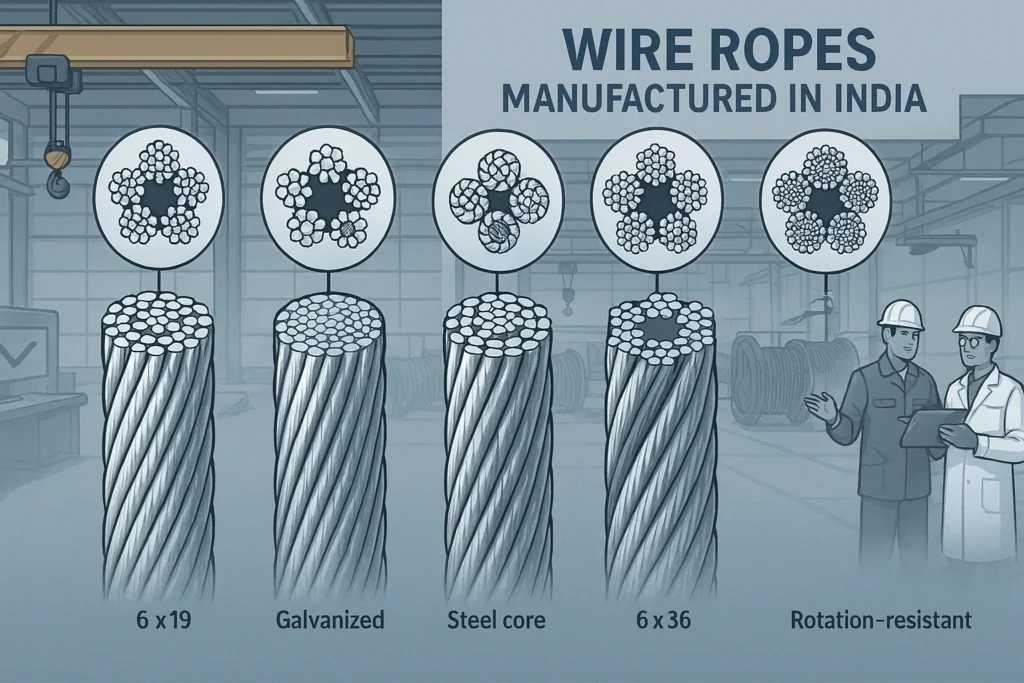

a. Wire Ropes

Wire ropes are essential for cranes, hoists, and winches. They offer flexibility, high tensile strength, and resistance to abrasion.

When selecting a wire rope:

- Choose the right construction (e.g., 6×19, 6×36) depending on the balance between flexibility and strength.

- Consider core type (fiber or steel) based on working conditions.

- Opt for galvanized or stainless steel wire ropes for corrosion-prone environments.

SVIBO Industries, one of the top wire rope manufacturers and suppliers in India, provides a complete range of ropes built to international standards, ensuring safety, precision, and durability.

b. Electric Chain Hoists

Electric chain hoists are widely used for lifting medium to heavy loads in factories, warehouses, and workshops. They provide controlled movement, efficiency, and safety compared to manual methods.

When choosing an electric chain hoist, consider:

- Load capacity: Ensure the hoist’s Working Load Limit (WLL) exceeds your maximum load.

- Lifting height: Choose appropriate lifting travel according to workspace requirements.

- Motor efficiency and speed control: Look for variable speed options for better precision.

- Safety features: Overload protection, emergency stop, and brake systems are essential.

As a reliable electric chain hoist manufacturer and supplier in India, SVIBO Industries delivers robust, efficient, and safety-tested hoists designed for continuous industrial operation.

c. Eye Bolts

Eye bolts are vital for attaching loads securely to hoists or slings. They come in various designs—shoulder eye bolts, lag eye bolts, and collar eye bolts—each suited for specific load directions and angles.

While choosing eye bolts:

- Match the thread size and material to the load and environment.

- Verify the Safe Working Load (SWL) and ensure proper alignment during installation.

- Use only certified bolts tested for lifting applications.

SVIBO Industries, a trusted eye bolt manufacturer and supplier in India, provides precision-engineered lifting accessories that meet both national and international standards.

Material and Construction Quality

The durability and safety of lifting gear depend heavily on its material and build quality.

- Steel Quality: Look for high-tensile alloy or carbon steel for heavy-duty applications.

- Surface Treatment: Galvanization, painting, or powder coating helps resist corrosion.

- Testing & Certification: Always verify that your supplier provides test certificates and adheres to ISO, IS, or EN standards.

SVIBO Industries ensures every product undergoes rigorous quality checks and proof load testing to guarantee superior performance and safety compliance.

Safety Standards and Inspection Practices

Safety is non-negotiable in any lifting operation. To maintain reliability:

- Inspect equipment before each use for wear, cracks, or deformation.

- Maintain a logbook of inspections and certifications.

- Replace worn-out parts immediately to avoid operational hazards.

- Ensure your team is trained in proper rigging and lifting techniques.

Following regular inspection protocols not only increases the lifespan of your equipment but also protects your workforce and assets.

Factors to Consider Before Purchase

When choosing the right lifting and rigging tools, keep these factors in mind:

- Load capacity and application type

- Environment (indoor/outdoor, humidity, chemicals)

- Ease of installation and maintenance

- Availability of spare parts

- Supplier reputation and after-sales service

With a strong manufacturing base and experienced engineering team, SVIBO Industries ensures every product—be it wire ropes, electric chain hoists, or eye bolts—is designed to deliver dependable performance for industrial needs.

Partnering with a Reliable Manufacturer

The success of your lifting operation depends not only on the right equipment but also on partnering with the right manufacturer.

At SVIBO Industries, quality, safety, and innovation are our top priorities. As a trusted name among lifting and rigging equipment manufacturers in India, we offer:

- Comprehensive product range: Wire ropes, hoists, slings, shackles, clamps, turnbuckles, and more.

- Stringent quality control: Every item is tested to meet international safety benchmarks.

- Customization: Tailored solutions to fit unique operational requirements.

- Timely delivery & support: Efficient logistics and responsive customer service.

Our commitment to excellence has made SVIBO a preferred choice for industries across India and overseas.

Conclusion

Selecting the right lifting and rigging equipment is not just about performance—it’s about safety, reliability, and efficiency. By understanding your operational needs and partnering with trusted experts like SVIBO Industries, you ensure long-term value and reduced downtime.

Whether you need wire ropes, electric chain hoists, or eye bolts, SVIBO delivers products built with precision and passion for industrial excellence.

Contact SVIBO Industries today to get expert assistance in choosing the perfect lifting solution for your business.