Bow Shackles

Svibo Industries is Broadly Known as Manufacturers , Importers and Suppliers for all types of Bow Shackles across India at Best Rates

Bow shackles, also known as anchor shackles, are essential components in lifting and rigging applications where secure connections and load distribution are paramount. These versatile connectors are widely used in industries such as construction, maritime, oil and gas, and manufacturing. Let’s delve into the features and benefits of bow shackles in load handling operations.

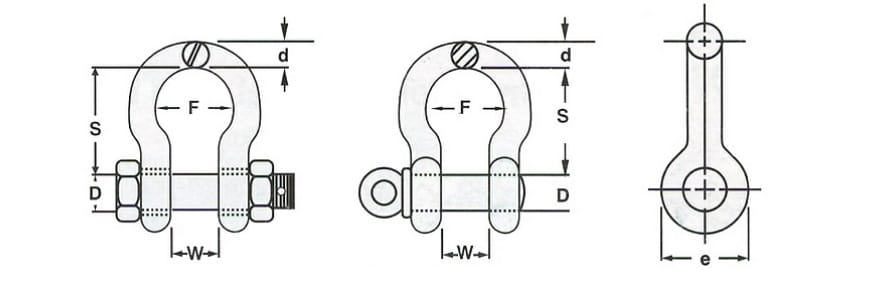

- Design and Construction: Bow shackles are named after their distinctive “bow” shape, featuring a rounded shape on one side and a straight, threaded pin on the other side. They are typically made from high-strength forged alloy steel or stainless steel to provide excellent strength, durability, and resistance to corrosion. This robust construction ensures that bow shackles can withstand heavy loads and harsh working conditions.

- Load Distribution: The rounded shape of bow shackles allows for even load distribution across the body, minimizing stress concentrations and reducing the risk of failure. This ensures that the load is evenly spread, preventing damage to the lifting or rigging equipment and promoting safe load handling.

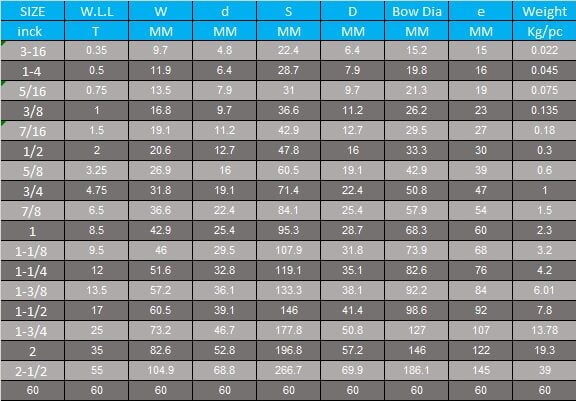

- Versatility: Bow shackles are available in various sizes and load capacities, making them suitable for a wide range of applications. They can be used to connect chains, wire ropes, slings, and other lifting components. Bow shackles can be used in both temporary and permanent connections, providing versatility and adaptability in different lifting and rigging setups.

- Secure Connection: Bow shackles feature a threaded pin that can be securely fastened, ensuring a reliable connection between lifting components. This threaded pin is typically secured with a cotter pin, split pin, or locking mechanism, providing added safety and preventing accidental disconnection during lifting operations.

- Safety Considerations: Bow shackles are designed with safety in mind. They often include load capacity markings to ensure proper usage and prevent overloading. It’s important to select bow shackles with load ratings that match the intended application to maintain safety and prevent equipment failure.

- Compliance with Standards: Bow shackles are manufactured to meet industry standards and regulations, such as those set by organizations like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO). Using bow shackles that comply with these standards ensures their reliability, performance, and safety.

Bow shackles are crucial components in a wide range of lifting and rigging operations. They provide secure and reliable connections, allowing for the safe movement of heavy loads. Whether it’s lifting equipment on construction sites, securing cargo on ships, or handling materials in industrial settings, bow shackles play a vital role in maintaining the integrity of the lifting system.