Wire Rope Thimble Manufacturers and Suppliers in India

- Home

- Wire Rope Thimble

Top Wire Rope Thimble Manufacturers and Suppliers in India – SVIBO Industries

SVIBO Industries is a trusted wire rope thimble manufacturers and suppliers in India, offering high-quality, durable thimbles that protect wire rope eyes and ensure safe, efficient lifting and rigging. Made from superior-grade steel, our thimbles are corrosion-resistant, strong, and ideal for industrial, construction, and marine applications.

Who Are the Top Wire Rope Thimble Manufacturers and Suppliers in India?

SVIBO Industries is recognized as one of the leading wire rope thimble manufacturers and suppliers in India. We provide high-quality, durable wire rope thimbles that ensure safety and reliability in lifting, rigging, and industrial applications. Our thimbles are precision-engineered to protect ropes from wear and extend their service life. With a focus on strength, performance, and cost-effectiveness, we cater to both standard and customized requirements. Choose SVIBO Industries for premium wire rope thimbles designed for long-lasting and secure operations.

Features & Benefits of Our Thimbles

Let’s explore the features, benefits, and considerations associated with wire rope thimbles.

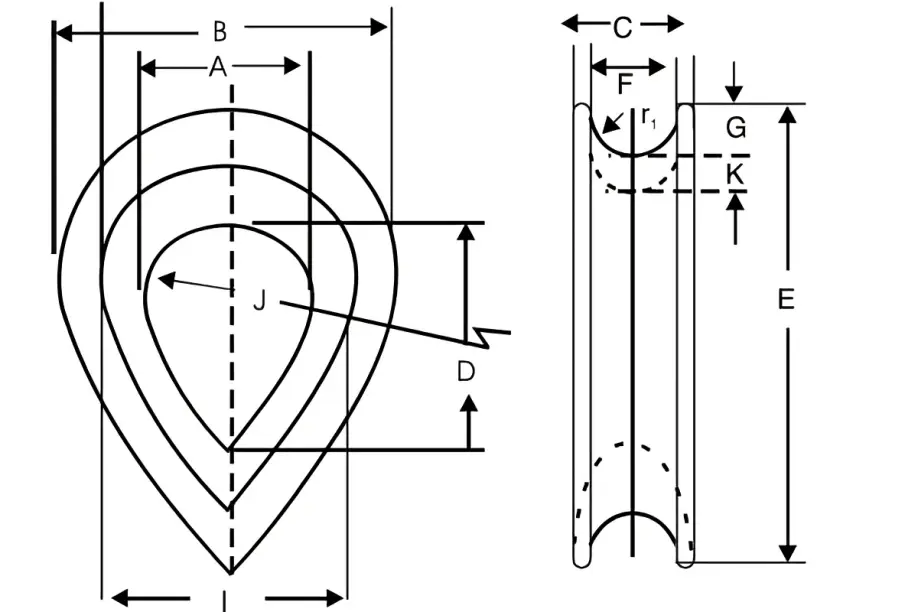

- Protection and Wear Reduction : Wire rope thimbles are designed to prevent wear and abrasion on wire rope loops. When a wire rope forms a loop or an eye termination, the thimble is inserted within the loop to provide a protective barrier between the wire rope and any surface it comes into contact with. This helps to minimize friction, abrasion, and damage to the wire rope, ensuring a longer lifespan and maintaining the overall strength and reliability of the assembly. SVIBO Industries, a leading manufacturer and supplier of wire rope thimbles in India, ensures every thimble is engineered to meet these exact standards for protection and durability.

- Enhanced Load Distribution : Thimbles also contribute to load distribution within the wire rope assembly. By guiding the wire rope through the curved channel of the thimble, the load is spread more evenly across the wire strands, reducing stress concentrations. This helps to prevent localized wear and prolongs the life of the wire rope.

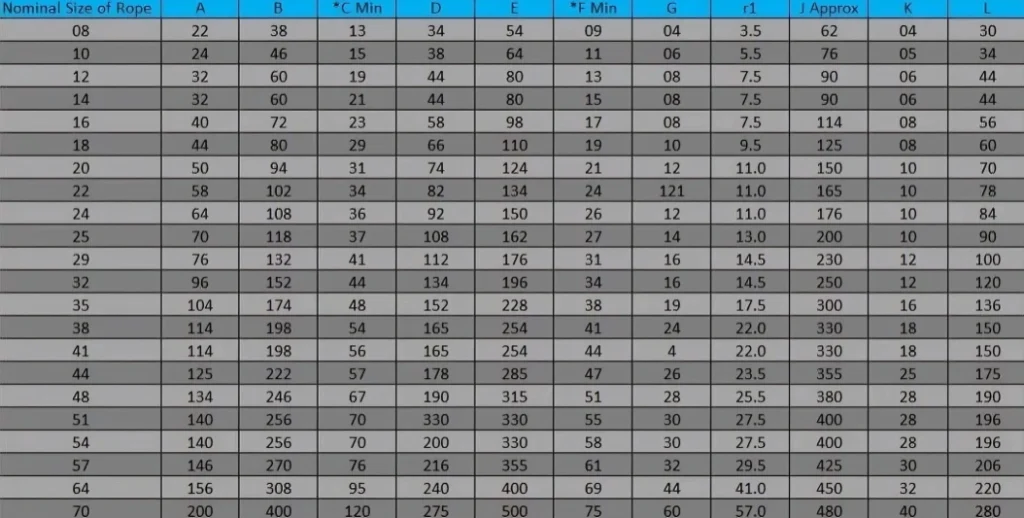

- Variety of Thimble Types : Wire rope thimbles come in various types to accommodate different applications and wire rope sizes. The most common types include standard thimbles, heavy-duty thimbles, and open-type thimbles. Standard thimbles are suitable for general-purpose use, heavy-duty thimbles offer increased strength and durability for demanding applications, and open-type thimbles allow for easier installation and inspection of the wire rope.

- Material Options : Wire rope thimbles are typically made from materials such as stainless steel, galvanized steel, or other corrosion-resistant alloys. The choice of material depends on the application requirements, environmental conditions, and desired level of corrosion resistance. Stainless steel thimbles are commonly used in marine and outdoor applications due to their excellent corrosion resistance.

- Easy Installation : Installing wire rope thimbles is a straightforward process. After forming the desired loop or eye termination in the wire rope, the thimble is inserted into the loop. The wire rope is then secured around the thimble using wire rope clamps or other appropriate fastening methods. It is essential to follow the manufacturer’s guidelines and recommended procedures for proper installation.

- Compatibility with Fittings : Wire rope thimbles are compatible with various wire rope fittings, including shackles, hooks, and connectors. They provide a secure and reliable connection point between the wire rope and the fitting, enhancing the overall strength and safety of the assembly.

- Inspection and Maintenance : Regular inspection of wire rope thimbles is essential to ensure their ongoing effectiveness. Inspect the thimble, wire rope, and associated components for signs of wear, deformation, or damage. If any issues are detected, replace the thimble promptly to maintain the integrity of the wire rope assembly.

By incorporating wire rope thimbles into wire rope loops and eye terminations, you can significantly enhance the durability, reliability, and lifespan of the wire rope. They provide vital protection against wear, distribute loads more evenly, and contribute to the overall strength and safety of the assembly. Whether in marine, construction, industrial, or other applications, wire rope thimbles are an indispensable part of maintaining the integrity of wire rope assemblies.

Your Reliable Partner for Wire Rope Thimbles

As trusted Wire Rope Thimble Manufacturers and Suppliers in India, SVIBO Industries delivers strong, precision-engineered thimbles that protect wire rope loops from wear and deformation. Our products are ideal for lifting, rigging, marine, and construction applications—ensuring safety, durability, and long-lasting performance.

Frequently Asked Questions (FAQs)

It reinforces the loop of a wire rope to prevent crushing and extend rope life.

Stainless steel thimbles (SS304/316) are ideal for corrosive and marine environments.

Yes, we offer a wide range of sizes to suit both light and heavy-duty applications.

Absolutely. Our thimbles meet international quality and safety standards.