Wire rope clamp manufacturers suppliers in India provide essential components for creating secure connections in wire rope assemblies. Also known as cable clamps or wire rope clips, these clamps consist of a U-shaped saddle, a threaded bolt, and a base plate. When properly installed, they offer a strong grip on the wire rope, preventing slippage or separation under load. These clamps are widely used across industries such as construction, maritime, oil and gas, and more.

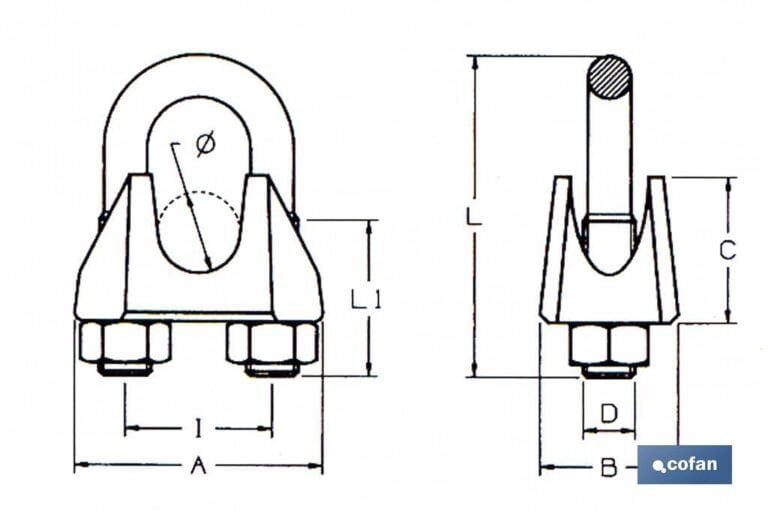

SVIBO Industries, a leading name among wire rope clamp manufacturers and suppliers in India, ensures each clamp is engineered for strength, safety, and durability. Our wire rope clamps are composed of the following precision components:

Wire rope clamps find widespread use in various industries and applications, including:

As one of the leading Wire Rope Clamp Manufacturers and Suppliers in India, SVIBO Industries is committed to delivering high-quality, durable, and precisely engineered solutions for various industrial applications. Our clamps ensure a secure grip, long service life, and excellent resistance to wear and corrosion.

Whether you need clamps for lifting, rigging, or fastening, we provide reliable products backed by expert support and prompt delivery across India.