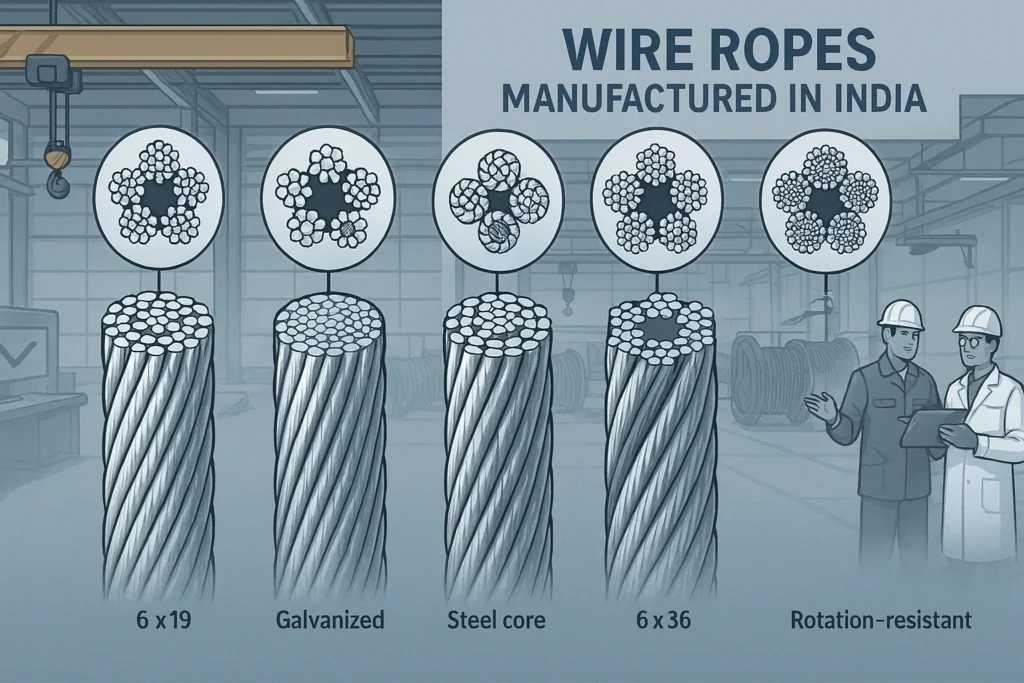

Wire ropes play a critical role in modern industries where lifting, pulling, suspension, and load handling are involved. From construction sites and mining operations to ports, oil & gas platforms, and manufacturing plants, wire ropes ensure safety, efficiency, and operational reliability. Leading wire rope manufacturers and suppliers in india offer a wide variety of wire ropes designed to meet diverse industrial needs, environmental conditions, and load requirements.

Understanding the different types of wire ropes available helps buyers select the right product for long-term performance, reduced downtime, and enhanced safety. This guide explores the most common types of wire ropes offered by top manufacturers in India and their applications.

What Is a Wire Rope?

A wire rope is a complex mechanical device made from multiple steel wires twisted together into strands, which are then laid around a central core. This construction provides exceptional tensile strength, flexibility, and resistance to wear, making wire ropes ideal for heavy-duty operations.

Indian manufacturers follow strict quality standards and advanced production techniques to ensure consistency, durability, and compliance with global safety norms.

1. Classification Based on Wire Rope Construction

6×19 Wire Rope

The 6×19 construction consists of six strands with 19 wires per strand. It offers a balance between strength and abrasion resistance.

Applications:

- Cranes and hoists

- Material handling equipment

- Winches and lifting machines

This type is widely used in general lifting applications where moderate flexibility is required.

6×36 Wire Rope

With more wires per strand, 6×36 wire ropes are more flexible than 6×19 constructions.

Applications:

- Construction cranes

- Mining equipment

- Offshore lifting operations

Their flexibility makes them suitable for applications involving bending over sheaves.

2. Based on Core Type

Fibre Core (FC) Wire Ropes

Fibre core wire ropes use natural or synthetic fibres at the center, providing enhanced flexibility and shock absorption.

Advantages:

- Lightweight

- High flexibility

- Better vibration damping

Applications:

- Light-duty lifting

- Elevators

- Industrial machinery

Steel Core Wire Ropes

Steel cores offer higher strength and heat resistance.

Types include:

- Independent Wire Rope Core (IWRC)

- Wire Strand Core (WSC)

Applications:

- Heavy lifting

- High-temperature environments

- Construction and mining

Steel core wire ropes are preferred for demanding industrial conditions.

3. Based on Surface Finish

Galvanized Wire Ropes

Galvanized wire ropes are coated with zinc to protect against corrosion.

Benefits:

- Excellent rust resistance

- Longer service life

- Suitable for outdoor use

Applications:

- Marine and port operations

- Coastal construction

- Power transmission

Ungalvanized (Bright) Wire Ropes

These wire ropes are untreated and offer higher fatigue resistance.

Applications:

- Indoor lifting

- Controlled industrial environments

- Cranes and hoists

4. Based on Lay Type

Regular Lay Wire Ropes

In regular lay ropes, wires are twisted in one direction while strands are twisted in the opposite direction.

Advantages:

- Stable structure

- Resistant to crushing

- Easy handling

These are commonly used in general-purpose lifting.

Lang Lay Wire Ropes

Here, both wires and strands are twisted in the same direction.

Advantages:

- Superior abrasion resistance

- Longer wear life

Applications:

- Draglines

- Excavators

- Mining operations

5. Rotation-Resistant Wire Ropes

Rotation-resistant wire ropes are specially designed to minimize twisting under load. They consist of multiple layers of strands laid in opposing directions.

Applications:

- Tower cranes

- High-rise construction

- Deep lifting operations

These ropes enhance safety where load stability is critical.

6. Specialized Wire Ropes for Industry-Specific Use

Leading manufacturers also offer application-specific wire ropes, such as:

- Elevator Wire Ropes – Designed for smooth movement and passenger safety

- Mining Wire Ropes – Built for extreme loads and harsh conditions

- Marine Wire Ropes – Corrosion-resistant for saltwater exposure

- Oil & Gas Wire Ropes – High-strength ropes for offshore and drilling operations

Trusted wire rope manufacturers and suppliers in india ensure these specialized products meet international standards like ISO, EN, and IS certifications.

7. Importance of Choosing the Right Wire Rope

Selecting the correct wire rope depends on several factors:

- Load capacity

- Operating environment

- Flexibility requirements

- Abrasion and corrosion exposure

- Safety regulations

Using the wrong type can lead to premature wear, safety hazards, and increased maintenance costs. This is why sourcing from experienced wire rope manufacturers and suppliers in india is essential for long-term performance and workplace safety.

Conclusion

India’s leading wire rope manufacturers offer a comprehensive range of products tailored to diverse industrial applications. From standard lifting wire ropes to specialized, rotation-resistant, and corrosion-proof variants, each type serves a specific purpose. Understanding these differences enables industries to make informed purchasing decisions, improve operational efficiency, and ensure safety compliance.

By choosing high-quality wire ropes manufactured with precision and tested for performance, businesses can achieve reliable load handling even in the most demanding environments.

FAQ

1. What are the main types of wire ropes used in India?

The most common types include 6×19 and 6×36 construction wire ropes, fibre core and steel core wire ropes, galvanized and ungalvanized wire ropes, and rotation-resistant wire ropes designed for specialized lifting applications.

2. Which wire rope is best for heavy lifting operations?

Steel core wire ropes, especially those with IWRC construction, are ideal for heavy lifting due to their high strength, durability, and resistance to heat and crushing.

3. Why are galvanized wire ropes preferred for outdoor use?

Galvanized wire ropes are coated with zinc, which protects them from corrosion and rust, making them suitable for marine, coastal, and outdoor industrial environments.

4. How do I select the right wire rope for my application?

Selection depends on load capacity, operating conditions, flexibility requirements, environmental exposure, and safety standards. Consulting experienced manufacturers ensures the right choice.

5. Do Indian wire rope manufacturers follow international quality standards?

Yes, leading manufacturers in India comply with standards such as IS, ISO, EN, and other global certifications to ensure safety, reliability, and performance.