In industrial settings, the movement of heavy objects is both commonplace and important. Maintaining safety and productivity requires that lifting tools be of the highest standard. In this regard, one of the most common tools used are pulley blocks, particularly the chain pulley blocks. These machines are great at minimizing the required labor while lifting, and doing so with more accuracy. Because of this, they are critical in construction, warehousing, automotive, and shipping industries.

Svibo Industries is one of the most trusted chain pulley block suppliers in India. He is quite aware of the need for reliable and effective lifting tools. In this regard, I will first explain what pulley blocks are, the ways they are used, the different types they come in, and their importance in lifting jobs. In the end, I will explain other tools used alongside them and their manufacturers.

What is a Pulley Block?

A pulley block is a mechanical device that is used in lifting or moving heavy objects. It performs this function by either employing a rope or a chain that is wound around one or more wheels. If more than one pulley is used, the device is referred to as a block and tackle, which is able to greatly lower the amount of force needed to lift a load.

Chain Pulley Blocks

Chain pulley blocks are among the most widely used systems of pulleys because of their efficiency, load harnessing strength, and vertical lift mechanics which greatly reduce the operator’s physical exertion. These blocks consist of:

- Lifting hook and gears

- Enclosed lifting mechanism for safety

- Hand chain (operated manually)

- Load chain (used to lift the weight)

Chain pulley blocks can be used for light duty and heavy duty tasks, particularly in the absence of a power supply and in situations where the operator prefers to have more manual control.

Industrial Applications of Pulley Blocks

Construction Industry

Chain pulley blocks are useful in lifting large structural materials like steel beams, concrete blocks and rebar which is often required in a construction site. These items need to be moved to a particular height and the blocks not only help lift but also allow greater control and safety while lifting in confined areas.

Manufacturing Plants

For factories, pulley blocks are useful in moving materials for various tasks of the assembly line as well as lifting heavy machinery for installation or servicing. While suppliers, like the Electric chain hoist manufacturers in India, provide automated alternatives, pulley blocks are the most preferred for manual tasks.

Warehousing and Logistics

Chain pulley blocks are vital to the warehousing section as they help in the loading as well as unloading of various materials. In addition, their compact design allows their use in fixed or moveable storage cranes, trolleys, or mounting storage units.

Marine and Shipbuilding

In shipyards and marine docks, pulley blocks play a crucial role in the process of rigging, hauling, and lifting engines, hulls, and other heavy machinery. These environments prefer the less corrosive models.

Mining and Heavy Industries

In mines, there are considerable risks. Pulley systems are important in the movement of earth, tools, and other machinery. These systems are essential in earth moving industries, especially with the active involvement of chain sling manufacturers in India.

How Chain Pulley Blocks Work

The hand chain gets pulled and in turn, the internal gear is turned. This process of turning transfers force to the load chain which in turn lifts the load that is attached to a bottom hook. Chain pulley blocks are based on a simple principle of physics, force is a need in every process and with proper mechanisms in place, the force can be redirected to boost the mechanical advantage.

The system’s ability to reduce the needed effort to lift a load, in some cases with a reduction of 5 or more, translates to ease in lifting several tons of weight in a managed manner.

Advantages of Using Chain Pulley Blocks

No power supply needed, making it particularly advantageous in remote and mobile working spaces.

- While lifting, lowering, or moving heavy load, control is maintained making the process efficient. This is a result of using chain pulley blocks.

- The body of chain blocks are made of steel which adds to the durability. The steel body is constructed with safety and braking systems which reinforces the body.

- Cost-Effective- More economical than electric lifting systems, particularly for operations conducted on a low- frequency basis.

- Versatility- Applicable for both indoor and outdoor settings, as well as for both temporary and permanent configurations.

Selecting a Supplier: Chain Pulley Block Supplier in India

A reliable supplier is important to guarantee lifting safety, long-term durability, and support services. An expert chain pulley block supplier in India, such as Svibo Industries, offers:

- The equipment is certified and load tested

- Custom load capacity ranging from 0.5 to 20 tons

- Adherence to national and international safety requirements

- Documentation for maintenance and spare part safekeeping

- Comprehensive manuals and documentation

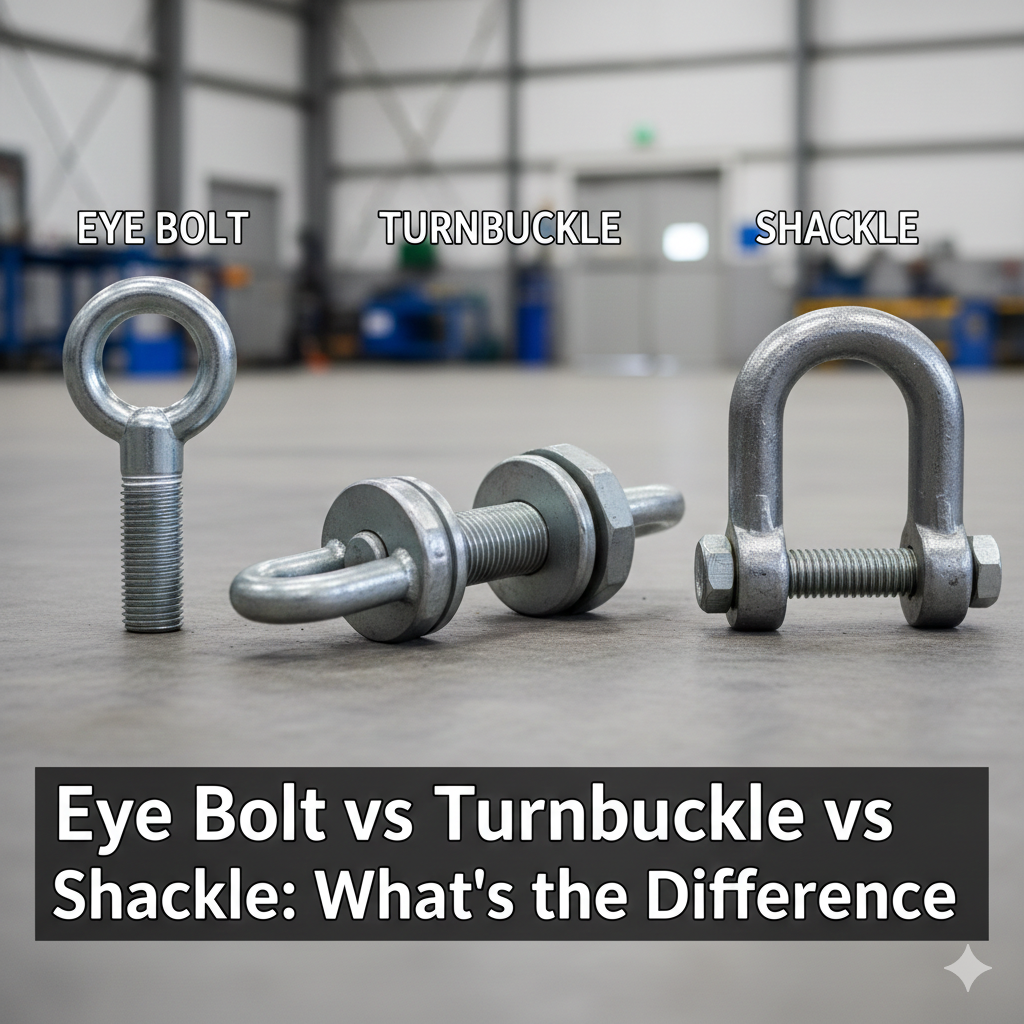

A good supplier also offers other rigging and lifting components. For example, wire rope clamp manufacturers suppliers in India or eye bolt manufacturer suppliers in India. This allows for all hardware to be sourced from a single point.

Associated Tools That Sometimes Accompany Pulley Blocks

Alongside other lifting equipment, chain pulley blocks have practical uses in lifting. Here are some:

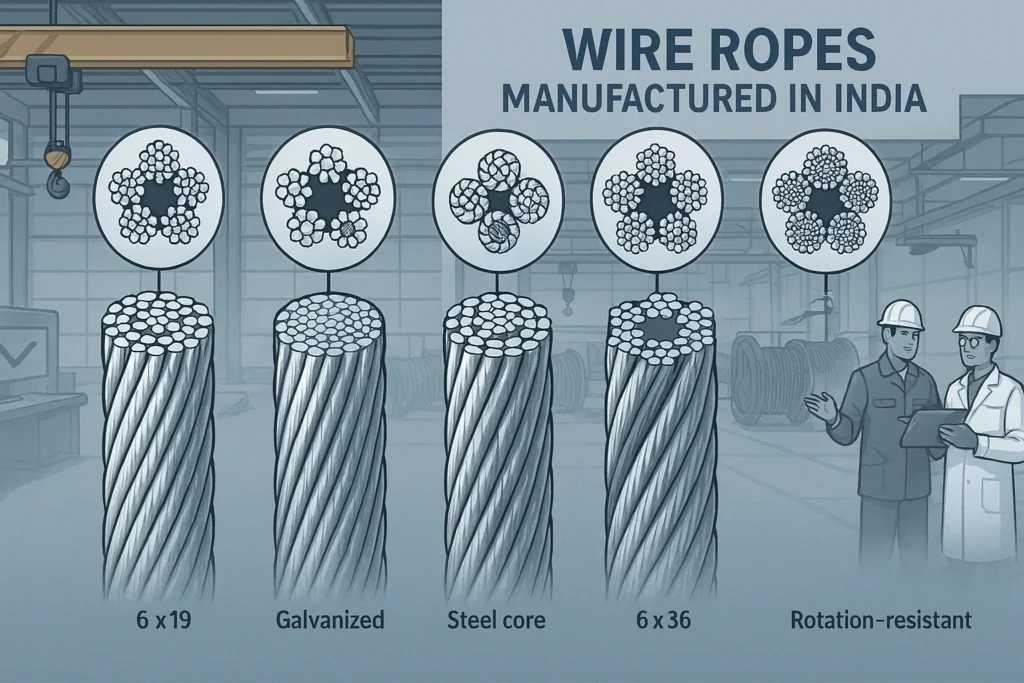

Used for hoisting and anchoring, wire ropes play an important part in most lifting arrangements. Quality wire rope manufacturers and suppliers in India offer corrosion-resistant, high-tensile wire ropes. There are also wire rope clamp manufacturers suppliers in India who provide accessories to properly finish and secure wire rope ends.

Chain Sling

In India, chain sling manufacturers suppliers design, and in India, they design slings to be used for connection with pulley hoisting systems onto the load. Slings are made in single leg or multi-leg configurations depending on the weight and the balance they bring on the load while suspended.

Other items referred to include severe duty system turnbuckle manufacturers in India and d shackle bow shackle manufacturers in India. They provide tensioning and secure connection turnbuckle and bow shackles that are important in dynamic lifting systems.

Electric Hoists

Electric chain hoist manufacturer suppliers in India provide automation tools for frequent or high load operations.

Safety Guidelines for Using Pulley Blocks

Always check parts for undue wearing, corrosion, deformities, or changes in physical structure.

- Do not exceed the manufacturer’s recommended load limit.

- Ensure all components like hooks, chains, and gears are clean and properly lubricated.

- For dependable anchoring, utilize compatible accessories such as wire rope thimble manufacturers and suppliers in India.

- Ensure proper training for all staff, including use and emergency response protocols.

- Common Mistakes to Avoid

- Using uncertified components.

- Ignoring scheduled maintenance.

- Using pulley blocks in angular or side-load positions.

- Failing to observe lifting point maintenance, including beams, hooks, slings, and slings.

Future of Industrial Lifting with Pulley Blocks

There will always be a place for manual chain pulley blocks in industries focused on simplicity and manual control. Safety and performance innovations are actively evolving, with integration of IoT, smart load monitoring, and hybrid systems (manual and electric) emerging.

Suppliers, like Svibo Industries, are meeting and anticipating the evolving demands of industries while adhering to safety regulations and quality standards.

Conclusion

In the manufacturing, logistics, construction, or shipbuilding industries, a chain pulley block supplier in India can help optimize operations with certified, tested, and performance-ready equipment.

Chain pulley blocks are versatile and reliable, and with proper pairing to accessories like chain slings, wire ropes, shackles, and turnbuckles, lifting tasks are performed with safety and productivity in mind.

Svibo Industries: Your One-Stop End-to-End Chain Pulley Block Supplier in India

Need a certified supplier of chain pulley blocks in India? Get in touch with Svibo Industries Round-the-clock support is offered for selecting and integrating equipment and components for smooth operations.