Eye bolts are small components, but their role in lifting and rigging operations is critical. Choosing the wrong eye bolt can lead to equipment damage, load failure, serious injuries, or even fatal accidents. Whether you are handling machinery, structural components, or heavy industrial loads, selecting the correct eye bolt is essential for safety, efficiency, and compliance with lifting standards.

This detailed guide will help you understand how to choose the right eye bolt for lifting applications by covering types, load ratings, material selection, installation practices, and safety considerations. By the end of this article, you will be able to make an informed decision suitable for your lifting requirements.

What Is an Eye Bolt?

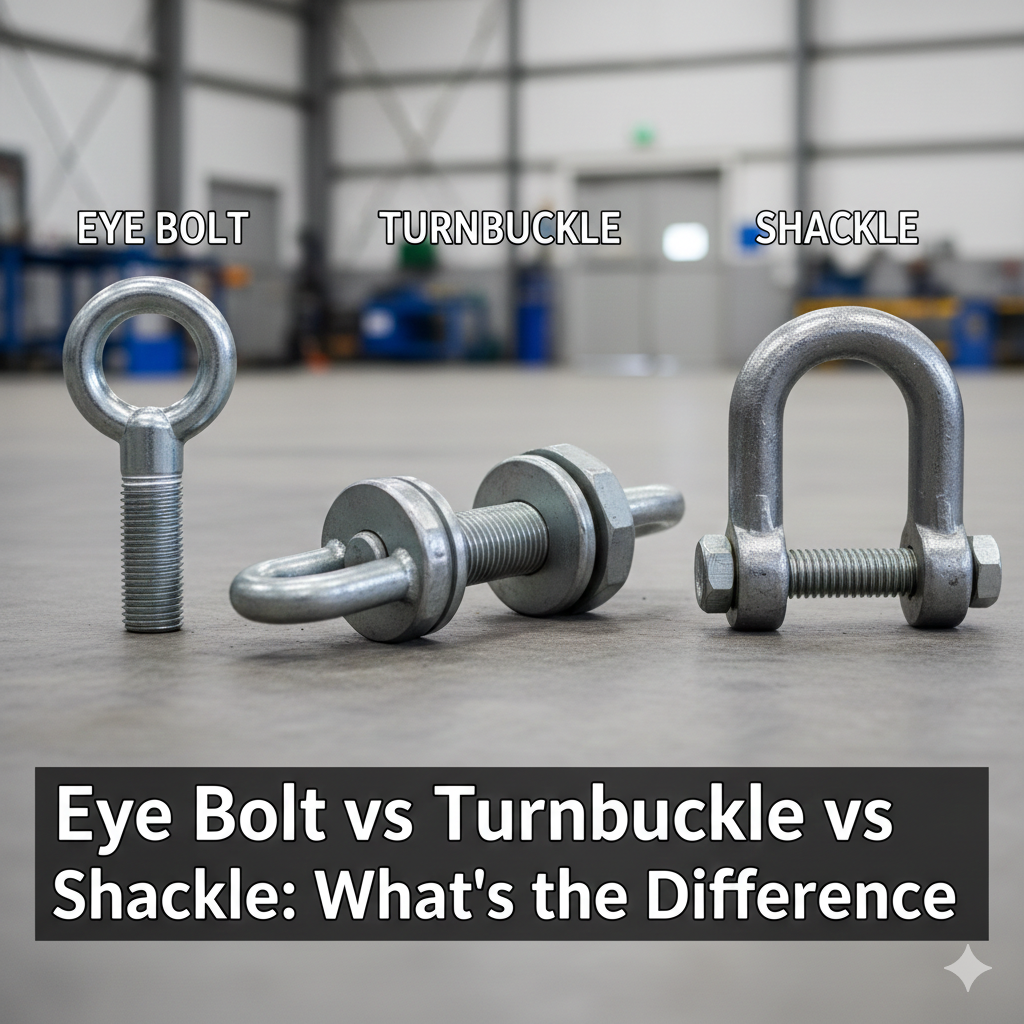

An eye bolt is a threaded fastener with a loop (eye) at one end. It is designed to provide a secure attachment point for hooks, ropes, chains, or wire ropes during lifting, pulling, or anchoring operations. Eye bolts are widely used across construction, manufacturing, power plants, shipping yards, and heavy engineering industries.

Eye bolts must be selected carefully based on load direction, weight, environment, and usage frequency. Not all eye bolts are designed for lifting, and using an incorrect type can be dangerous.

Why Choosing the Right Eye Bolt Matters

Selecting the right eye bolt is not just a technical choice—it is a safety decision. Incorrect selection can result in:

- Load slippage or rotation

- Deformation or bending of the bolt

- Thread failure

- Sudden breakage during lifting

Proper eye bolt selection ensures:

- Safe load handling

- Compliance with industry standards

- Longer equipment lifespan

- Reduced downtime and accidents

This is why professionals prefer sourcing products from trusted eye bolt manufacturer suppliers in india that follow strict quality and safety standards.

Step 1: Understand the Types of Eye Bolts

The first step in choosing the right eye bolt is understanding the different types available and their specific applications.

1. Plain (Non-Shoulder) Eye Bolts

Plain eye bolts do not have a shoulder between the eye and the threaded shank. These are suitable only for straight, vertical lifts.

Key features:

- Designed for vertical loading only

- Not recommended for angular or side loading

- Commonly used for light-duty lifting

Using a plain eye bolt for angled lifting can significantly reduce its load capacity and increase the risk of failure.

2. Shoulder Eye Bolts

Shoulder eye bolts include a shoulder that provides additional support against angular loads.

Key features:

- Suitable for vertical and angular lifting

- Can handle limited side loading

- Widely used in industrial lifting operations

When loads are not perfectly vertical, shoulder eye bolts are the safer and more reliable option.

3. Machinery Eye Bolts

Machinery eye bolts are specifically designed for lifting motors, pumps, gearboxes, and heavy equipment.

Key features:

- High load-bearing capacity

- Precision threads for secure fastening

- Often used for permanent lifting points

These eye bolts are commonly used during installation, maintenance, and relocation of machinery.

4. Dynamo Eye Bolts

Dynamo eye bolts are heavy-duty lifting fasteners designed for demanding industrial applications.

Key features:

- Forged construction for high strength

- Ideal for repeated lifting operations

- Suitable for dynamic loads

They are often preferred in construction and infrastructure projects.

Step 2: Determine the Load Weight

Understanding the weight of the load is critical before selecting an eye bolt. The eye bolt must be capable of handling the load safely with an adequate safety factor.

Working Load Limit (WLL)

The Working Load Limit is the maximum load an eye bolt can safely handle under normal operating conditions.

Important points:

- Never exceed the WLL

- Consider the total weight, including attachments

- Account for dynamic forces such as shock loading

Choosing eye bolts with higher load ratings provides an additional margin of safety.

Step 3: Consider the Load Direction

Load direction has a major impact on eye bolt performance.

Vertical Loading

- Load applied directly in line with the shank

- Highest load capacity

- Plain and shoulder eye bolts can be used

Angular Loading

- Load applied at an angle to the shank

- Reduces load capacity significantly

- Only shoulder eye bolts should be used

As the angle increases, the effective load capacity decreases. Always refer to manufacturer load charts for angular loading limits.

Step 4: Choose the Right Material

Eye bolts are manufactured in different materials depending on the application environment.

Carbon Steel

- Commonly used for general lifting

- Strong and cost-effective

- Suitable for indoor and controlled environments

Alloy Steel

- High tensile strength

- Suitable for heavy-duty and high-load applications

- Used in demanding industrial environments

Stainless Steel

- Corrosion-resistant

- Ideal for marine, chemical, and outdoor applications

- Lower load capacity compared to alloy steel

Material selection should consider exposure to moisture, chemicals, heat, and corrosion.

Step 5: Check Thread Type and Length

Thread compatibility is crucial for safe installation.

Thread Type

- Metric threads (commonly used in India)

- Ensure compatibility with the tapped hole

Thread Length

- Threads must fully engage with the base material

- Inadequate thread engagement can cause pull-out failure

The eye bolt should seat flush against the mounting surface, especially for shoulder eye bolts.

Step 6: Follow Proper Installation Practices

Even the highest-quality eye bolt can fail if installed incorrectly.

Installation Best Practices

- Ensure the mounting surface is flat and clean

- Fully tighten the eye bolt so the shoulder rests firmly

- Do not use washers under shoulder eye bolts

- Align the eye with the direction of pull

Improper installation is one of the most common causes of eye bolt failure.

Step 7: Inspect Before Every Lift

Regular inspection is essential for safe lifting operations.

Inspection Checklist

- Look for cracks, bends, or deformation

- Check threads for wear or damage

- Ensure no corrosion or rust buildup

- Verify markings and load ratings

Eye bolts showing any sign of damage should be removed from service immediately.

Safety Standards and Compliance

Eye bolts used for lifting should comply with recognized standards such as:

- DIN standards

- IS specifications

- Manufacturer-certified load ratings

Reputable eye bolt manufacturer suppliers in india ensure their products meet these standards through rigorous testing and quality control.

Common Mistakes to Avoid

Many lifting accidents occur due to simple mistakes that can be avoided.

Avoid These Errors:

- Using plain eye bolts for angular loads

- Exceeding the working load limit

- Improper thread engagement

- Ignoring inspection and maintenance

- Using uncertified or low-quality products

Awareness and proper training significantly reduce risks associated with lifting operations.

Applications of Eye Bolts Across Industries

Eye bolts are used in a wide range of industries, including:

- Construction and infrastructure

- Manufacturing and assembly plants

- Power generation and utilities

- Oil and gas facilities

- Warehousing and logistics

Each application requires careful selection based on load type, environment, and usage frequency.

Why Source from Trusted Manufacturers and Suppliers

Quality, consistency, and compliance are essential when it comes to lifting hardware. Trusted eye bolt manufacturer suppliers in india provide:

- Precision-engineered products

- Certified load ratings

- Compliance with safety standards

- Technical support and documentation

Choosing reliable suppliers ensures long-term safety and performance.

Final Thoughts

Choosing the right eye bolt for lifting applications involves much more than selecting a size or type. It requires a clear understanding of load weight, direction, material, installation practices, and safety standards. A carefully selected and properly installed eye bolt ensures secure lifting, reduces operational risks, and enhances overall efficiency.

By following the guidelines outlined in this article and sourcing from reliable manufacturers, you can ensure safe and effective lifting operations across all industrial applications.

FAQ

1. What is the best eye bolt for lifting heavy loads?

Shoulder eye bolts made from alloy steel are best for lifting heavy loads, especially when angular lifting is required. They offer higher strength and better load distribution.

2. Can plain eye bolts be used for lifting?

Plain eye bolts should only be used for vertical lifting. They are not designed for angular or side loading and can fail if misused.

3. How do I know the load capacity of an eye bolt?

The load capacity is indicated by the Working Load Limit (WLL), which is provided by the manufacturer. Always ensure the load does not exceed the WLL.

4. Why is shoulder seating important during installation?

Proper shoulder seating ensures even load transfer and prevents bending or thread failure during lifting operations.

5. Which industries commonly use eye bolts in India?

Eye bolts are widely used in construction, manufacturing, power plants, oil & gas, warehousing, and heavy engineering industries.

6. How often should eye bolts be inspected?

Eye bolts should be inspected before every lifting operation and regularly checked for wear, cracks, corrosion, or thread damage.