Steel wire ropes play a critical role in lifting, rigging, material handling, construction, mining, marine, and industrial operations. Selecting the right manufacturer is not just about pricing—it directly impacts safety, performance, and long-term operational efficiency. With many suppliers available in the market, making the right choice requires careful evaluation.

This guide will help you understand how to choose the best Steel Wire Rope Manufacturers, ensuring quality, compliance, and reliability for your industrial needs.

1. Understand Your Application Requirements

Before shortlisting manufacturers, clearly define your application. Steel wire ropes are designed differently depending on their end use.

Consider factors such as:

- Load capacity and breaking strength

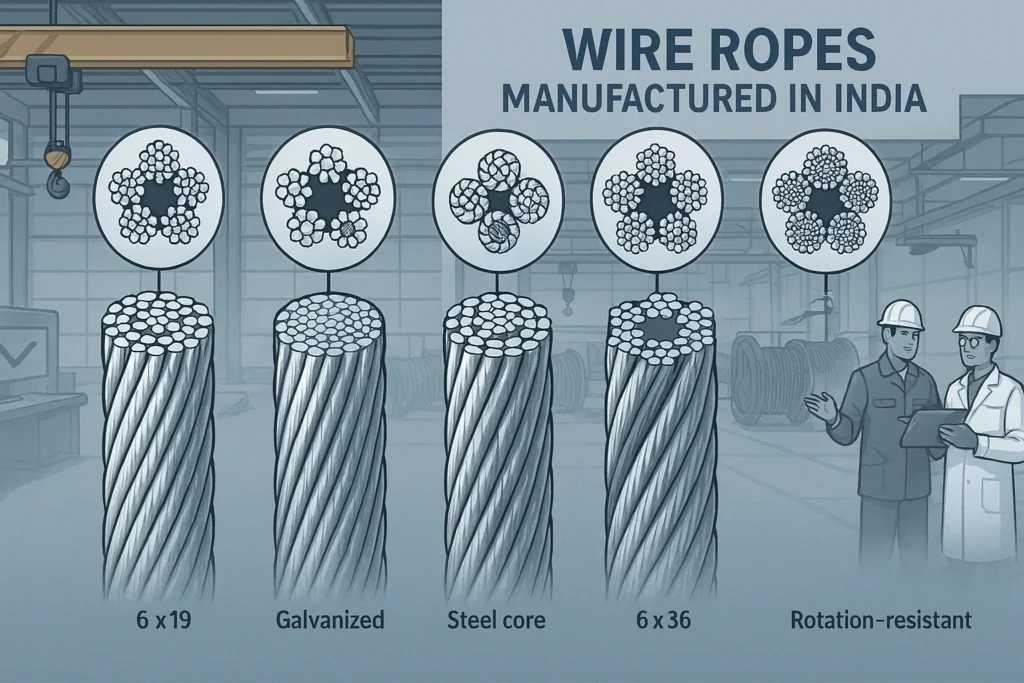

- Rope construction (6×19, 6×36, 8×19, etc.)

- Core type (Fiber Core, Steel Core, IWRC)

- Operating environment (marine, mining, outdoor, corrosive conditions)

- Flexibility and abrasion resistance

Reliable manufacturers will always ask about these requirements before recommending a product. This shows technical expertise and customer-focused service.

2. Evaluate Manufacturing Standards and Quality Control

One of the most important factors when choosing a manufacturer is adherence to international and national quality standards.

Reputed Steel Wire Rope Manufacturers follow strict quality control measures at every stage of production, including:

- Raw material inspection

- Wire drawing and stranding checks

- Load testing and breaking strength verification

- Dimensional accuracy and surface finish inspections

Look for manufacturers that comply with standards such as IS, EN, DIN, or ASTM, depending on your industry requirements. A strong quality assurance system ensures consistent performance and longer service life.

3. Check Certifications and Compliance

Certifications are proof of a manufacturer’s commitment to safety and quality. Trusted wire rope manufacturers and suppliers in india provide test certificates, material traceability, and compliance documentation with every order.

Key certifications to look for include:

- ISO certification

- Third-party inspection reports

- Mill test certificates

- Proof load and breaking load test results

These documents are especially critical for industries like construction, oil & gas, ports, and heavy engineering, where safety is non-negotiable.

4. Assess Industry Experience and Reputation

Experience matters when it comes to manufacturing high-performance steel wire ropes. Manufacturers with years of industry exposure understand complex applications and evolving safety requirements.

To evaluate reputation:

- Review client testimonials and case studies

- Check industries served (construction, mining, marine, power plants)

- Assess long-term partnerships with OEMs or EPC contractors

Established wire rope manufacturers and suppliers in india are more likely to deliver consistent quality, technical support, and reliable after-sales service.

5. Product Range and Customization Capabilities

The best manufacturers offer a wide product portfolio to meet diverse industrial needs. This includes:

- Galvanized and ungalvanized steel wire ropes

- Rotation-resistant wire ropes

- Crane wire ropes

- Elevator wire ropes

- Customized lengths and end fittings

Manufacturers with in-house customization capabilities can tailor wire ropes based on load, diameter, construction, and application-specific requirements, reducing downtime and improving operational efficiency.

6. Manufacturing Infrastructure and Technology

Advanced manufacturing facilities are a strong indicator of product reliability. Modern machinery, automated stranding lines, and testing equipment ensure precision and consistency.

When choosing a manufacturer, check whether they invest in:

- Modern wire drawing and closing machines

- In-house testing laboratories

- Skilled technical workforce

- Continuous process improvement

Technologically advanced manufacturers are better equipped to meet large-volume orders and stringent quality benchmarks.

7. Focus on Safety and Technical Support

Safety is the backbone of steel wire rope applications. The best manufacturers don’t just sell products—they provide technical guidance.

A reliable manufacturer will assist with:

- Proper rope selection

- Installation and handling guidelines

- Maintenance and inspection recommendations

- Load calculation support

This level of technical expertise minimizes failure risks and extends the service life of the wire rope.

8. Compare Pricing Without Compromising Quality

While pricing is important, choosing the cheapest option can lead to higher long-term costs due to frequent replacements or failures.

Instead:

- Compare price vs quality

- Understand what is included (testing, certification, packaging)

- Evaluate lifecycle cost rather than initial cost

Trusted manufacturers offer competitive pricing without compromising on material quality or safety standards.

9. Logistics, Delivery, and After-Sales Service

Timely delivery and responsive support are crucial for industrial projects. Delays can halt operations and increase costs.

Choose manufacturers that provide:

- Reliable delivery timelines

- Strong packaging to prevent damage

- Quick response to technical queries

- Consistent after-sales support

Professional service reflects a manufacturer’s commitment to long-term customer relationships.

10. Why Choosing the Right Manufacturer Matters

Selecting the right steel wire rope manufacturer ensures:

- Enhanced workplace safety

- Reduced downtime

- Better load performance

- Compliance with industry regulations

- Long-term cost savings

Investing time in selecting a reliable supplier leads to smoother operations and peace of mind.

Frequently Asked Questions

1. How do I identify reliable Steel Wire Rope Manufacturers in India?

Look for manufacturers with strong certifications, quality control systems, industry experience, and positive client feedback. Reliable suppliers also provide complete test documentation.

2. Why are certifications important when buying steel wire ropes?

Certifications confirm that the wire rope meets safety, strength, and quality standards, reducing the risk of failure in critical lifting applications.

3. Can steel wire ropes be customized for specific applications?

Yes, leading manufacturers offer customized wire ropes based on diameter, construction, load capacity, and application requirements.

4. What industries commonly use steel wire ropes?

Steel wire ropes are widely used in construction, mining, marine, ports, oil & gas, power plants, elevators, and material handling industries.

5. How often should steel wire ropes be inspected or replaced?

Inspection frequency depends on usage and environment. Regular inspections and timely replacement are essential to maintain safety and performance.

Final Note

Choosing the right steel wire rope manufacturer is a strategic decision that impacts safety, productivity, and operational success. By focusing on quality standards, certifications, experience, and technical support, you can confidently partner with a manufacturer that delivers long-term value.