Quality testing is one of the most critical stages in the wire rope manufacturing and supply process. Since wire ropes are widely used in lifting, hoisting, construction, mining, marine, oil & gas, and material handling applications, even a minor defect can lead to serious safety risks, equipment failure, or costly downtime. That is why thorough inspection and testing before dispatch is not optional—it is essential.

Leading wire rope manufacturers and suppliers in India follow a strict, multi-level quality control process to ensure every wire rope delivered meets required strength, durability, and safety standards. This blog explains, in detail, how quality testing is performed before dispatch, why it matters, and what buyers should look for when sourcing wire ropes.

Why Quality Testing Before Dispatch Is Critical

Wire ropes are subjected to extreme operating conditions such as heavy loads, continuous friction, bending stress, corrosion, and exposure to harsh environments. Without proper testing, defects like internal wire breaks, uneven strands, improper lubrication, or low tensile strength may go unnoticed until failure occurs.

Quality testing before dispatch ensures:

- Safe working load (SWL) compliance

- Long service life

- Consistent performance in demanding environments

- Compliance with national and international standards

- Reduced risk of accidents and liability

Stage 1: Raw Material Inspection

Quality testing begins long before the wire rope is manufactured. The first step is inspecting raw materials, primarily high-carbon steel wire rods.

What Is Checked?

- Chemical composition of steel

- Tensile strength of wire rods

- Surface finish and cleanliness

- Dimensional accuracy

Only approved-grade steel that meets required specifications is allowed for production. Any deviation at this stage can compromise the final product’s strength and flexibility.

Stage 2: Wire Drawing & Tensile Strength Testing

Once the steel rods pass inspection, they undergo wire drawing to achieve the required diameter. After drawing, tensile strength tests are conducted.

Tensile Strength Testing Includes:

- Measuring breaking force of individual wires

- Checking elongation under load

- Ensuring uniform strength across batches

This step ensures that each wire can withstand the required load without deformation or premature failure.

Stage 3: Strand Formation Inspection

Individual wires are twisted together to form strands. At this stage, manufacturers inspect the consistency and geometry of the strands.

Key Parameters Checked:

- Uniform wire lay

- Proper wire alignment

- Absence of loose or protruding wires

- Strand diameter accuracy

Consistent strand formation is essential for flexibility, load distribution, and fatigue resistance.

Stage 4: Wire Rope Construction Verification

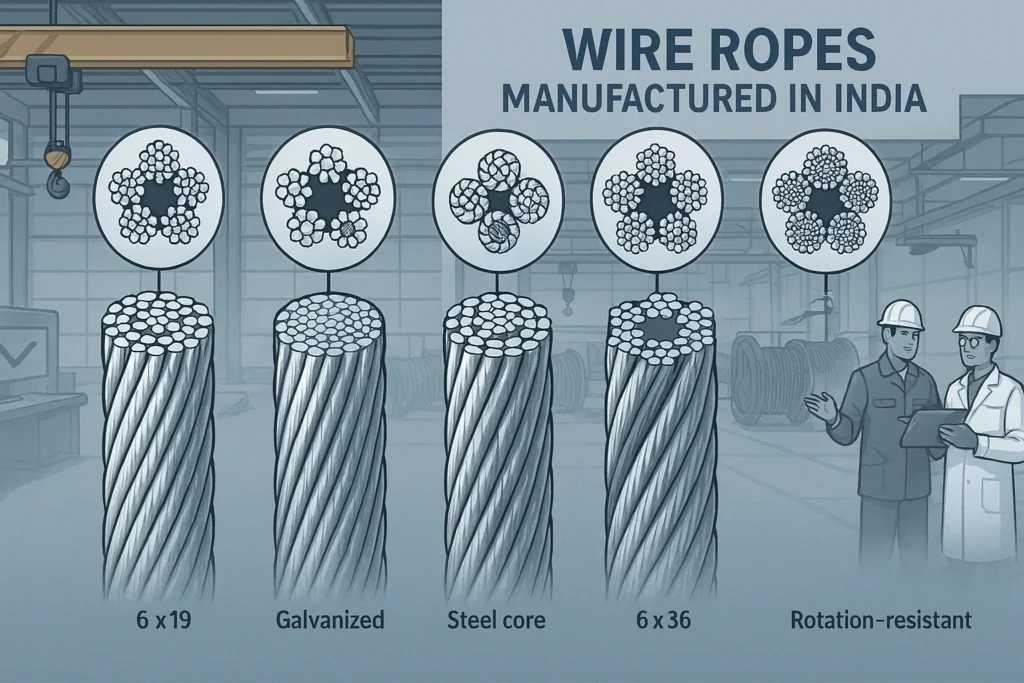

Strands are then laid around a core (fiber core, wire strand core, or independent wire rope core). This is a crucial stage where construction accuracy is verified.

Construction Checks Include:

- Correct rope construction (e.g., 6×19, 6×36, etc.)

- Proper lay direction (right or left-hand lay)

- Uniform strand tension

- Core alignment and stability

Any construction error at this stage can significantly reduce rope performance.

Stage 5: Diameter & Dimensional Inspection

After the wire rope is fully formed, dimensional checks are carried out to ensure compliance with specifications.

Measurements Taken:

- Rope diameter tolerance

- Roundness and consistency

- Length accuracy

These checks ensure the wire rope fits perfectly with sheaves, drums, and lifting equipment without excessive wear.

Stage 6: Lubrication & Surface Quality Testing

Lubrication plays a key role in extending wire rope life. Before dispatch, surface condition and lubrication quality are carefully examined.

Surface Testing Covers:

- Proper internal and external lubrication

- Smooth surface finish

- Absence of rust, cracks, or surface defects

- Uniform coating in galvanized ropes

Adequate lubrication reduces friction, prevents corrosion, and improves fatigue resistance.

Stage 7: Breaking Load Testing

Breaking load testing is one of the most important quality checks performed before dispatch. A sample wire rope is tested under controlled conditions until failure.

Purpose of Breaking Load Test:

- Verify minimum breaking force

- Confirm compliance with standards

- Ensure safety margins above SWL

Only wire ropes that meet or exceed the required breaking load are approved for dispatch.

Stage 8: Non-Destructive Testing (NDT)

In many cases, non-destructive testing methods are used to detect internal defects without damaging the rope.

Common NDT Methods:

- Visual inspection

- Magnetic rope testing (where applicable)

- Surface flaw detection

These tests help identify internal wire breaks, corrosion, or inconsistencies that are not visible externally.

Stage 9: Compliance With Standards & Specifications

Before dispatch, every batch of wire ropes is verified against applicable standards.

Common Standards Followed:

- IS (Indian Standards)

- ISO standards

- Customer-specific technical requirements

Compliance ensures the wire rope is suitable for its intended application and accepted in audits or project approvals.

Stage 10: Documentation & Test Certification

No wire rope should leave the facility without proper documentation.

Documents Typically Provided:

- Mill test certificate

- Breaking load test report

- Material traceability details

- Compliance declaration

Trusted wire rope manufacturers and suppliers in India ensure full transparency by providing complete documentation with every dispatch.

Stage 11: Packing & Pre-Dispatch Inspection

Before shipment, a final inspection is conducted to ensure the wire rope is properly packed and protected.

Final Checks Include:

- Correct labeling and tagging

- Secure coiling or drum packing

- Moisture and damage protection

- Verification of order quantity

This step prevents transit damage and ensures the product reaches the customer in perfect condition.

How Buyers Benefit From Pre-Dispatch Quality Testing

When quality testing is performed correctly, buyers gain:

- Improved operational safety

- Reduced maintenance costs

- Longer wire rope lifespan

- Compliance with safety audits

- Confidence in supplier reliability

This is why selecting experienced wire rope manufacturers and suppliers in India with robust quality systems is critical for industrial buyers.

Conclusion

Quality testing before dispatch is a comprehensive, multi-stage process that ensures wire ropes meet strict safety, strength, and performance requirements. From raw material inspection to breaking load tests and final documentation, every step is designed to eliminate risk and deliver dependable products.

For industries that rely on lifting and load-bearing operations, understanding this process helps in choosing the right supplier, avoiding failures, and ensuring long-term operational efficiency.

Frequently Asked Questions

1. Why is breaking load testing important before dispatch?

Breaking load testing confirms that the wire rope can safely handle loads beyond its rated capacity, ensuring a high safety margin during use.

2. Are all wire ropes tested individually before dispatch?

Not every rope is destructively tested, but samples from each batch are tested to ensure consistency and compliance.

3. What standards should wire ropes comply with?

Wire ropes typically comply with IS, ISO, or customer-specified standards depending on application requirements.

4. Is lubrication checked during quality testing?

Yes, lubrication is inspected to ensure corrosion resistance, reduced friction, and extended service life.

5. Do suppliers provide test certificates with dispatch?

Reputed manufacturers always provide test certificates and compliance documents along with the supplied wire ropes.