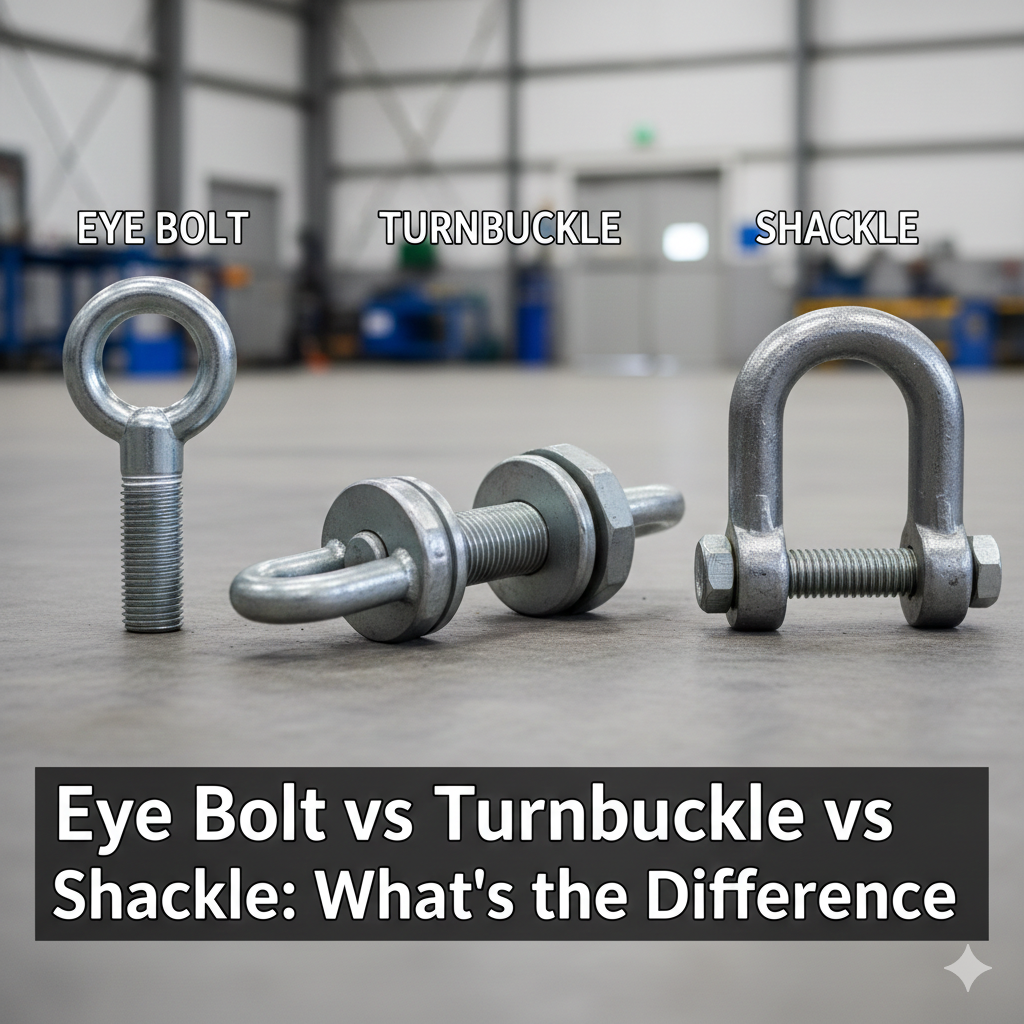

In lifting, rigging, and material handling applications, choosing the right hardware component is critical for safety, load efficiency, and compliance. Eye bolts, turnbuckles, and shackles are commonly used—but they serve very different purposes.

This guide explains the key differences, applications, and selection criteria to help you choose the right component for your industrial needs.

What Is an Eye Bolt?

An eye bolt is a threaded fastener with a loop (eye) at one end, designed primarily for lifting, anchoring, or securing loads.

Key Features:

- Threaded shank for mounting into a structure or machinery

- Circular eye for attaching hooks, slings, or ropes

- Available as plain eye bolts or shoulder eye bolts

- Manufactured in carbon steel, alloy steel, or stainless steel

Common Applications:

- Vertical lifting of machinery and equipment

- Anchoring heavy loads

- Construction and infrastructure projects

- Power plants and manufacturing units

👉 Eye bolts are best used when the load direction is vertical or near-vertical.

What Is a Turnbuckle?

A turnbuckle is a tensioning device used to adjust the length and tension of wire ropes, rods, or cables.

Key Features:

- Central body with internal threads

- Two end fittings (eye, hook, jaw, or hook-eye combinations)

- Allows precise tension adjustment by rotating the body

- Available in light-duty and heavy-duty designs

Common Applications:

- Structural bracing

- Transmission lines

- Suspension systems

- Marine and architectural applications

👉 Turnbuckles are ideal when load alignment or tension adjustment is required.

What Is a Shackle?

A shackle is a U-shaped or bow-shaped metal connector secured with a pin or bolt, widely used in rigging and lifting assemblies.

Key Features:

- Removable pin for easy connection and disconnection

- Available as D shackles or bow shackles

- High load-bearing capacity

- Designed for temporary or frequent rigging setups

Common Applications:

- Crane lifting operations

- Rigging and slinging systems

- Construction and offshore projects

- Towing and recovery operations

👉 Shackles are best for connecting lifting slings, chains, or ropes.

| Feature | Eye Bolt | Turnbuckle | Shackle |

|---|---|---|---|

| Primary Function | Lifting & anchoring | Tension adjustment | Load connection |

| Threaded Component | Yes | Yes (internal) | No |

| Adjustability | No | Yes | No |

| Load Direction | Vertical | Tension-based | Multi-directional |

| Installation | Permanent / Semi-permanent | Adjustable | Temporary |

| Safety Factor | High (if used correctly) | High | Very High |

Which One Should You Choose?

Choose an Eye Bolt if:

- You need a fixed lifting point

- Load direction is vertical

- Permanent or semi-permanent installation is required

Choose a Turnbuckle if:

- Tension adjustment is needed

- Cable or wire rope length must be controlled

- Structural alignment is critical

Choose a Shackle if:

- You need quick and secure connections

- Loads change frequently

- Rigging flexibility is required

Safety & Compliance Considerations

- Always verify Working Load Limit (WLL)

- Use products compliant with IS, DIN, ASTM standards

- Avoid side loading unless specified

- Regular inspection for cracks, deformation, or corrosion

- Use certified components from a reliable supplier in India

Conclusion

While eye bolts, turnbuckles, and shackles may look similar, each serves a distinct function in lifting and rigging systems. Selecting the correct component improves operational safety, efficiency, and equipment lifespan.

For industrial projects, working with a trusted Eye Bolt, Turnbuckle, and Shackle supplier in India ensures quality, compliance, and peace of mind.

By SVIBO Industries – Trusted Manufacturer & Supplier of Industrial Lifting Hardware in India

In lifting, rigging, and material handling operations, selecting the right hardware component is critical for safety, load efficiency, and compliance. Eye bolts, turnbuckles, and shackles are commonly used across industries—but each serves a distinct purpose.

At SVIBO Industries, we help engineering teams, EPC contractors, and industrial buyers choose the right solution based on application, load requirements, and safety standards.