Eye bolt manufacturers, suppliers in India

Leading Eye Bolt Manufacturers and Suppliers in India, offering durable and precision-engineered lifting solutions for industrial applications at competitive prices. SVIBO Industries is a leading Eye Bolt Manufacturer in India and a reliable Eye Bolt Supplier in India, offering precision-engineered eye bolts designed for strength, safety, and durability. Our eye bolts are manufactured using high-quality raw materials and advanced production techniques to meet national and international standards.

Who Are the Best Eye Bolt Manufacturers & Suppliers in India Offering the Best Rates?

SVIBO Industries is among the best eye bolt manufacturers and suppliers in India, known for delivering high-quality products at competitive rates. Using premium raw materials and strict quality control, SVIBO manufactures eye bolts that ensure strength, safety, and durability. With efficient production and customization capabilities, the company serves construction, manufacturing, marine, power, and oil & gas industries while offering reliable supply, timely delivery, and excellent value.

Key Features and Uses of Eye Bolts

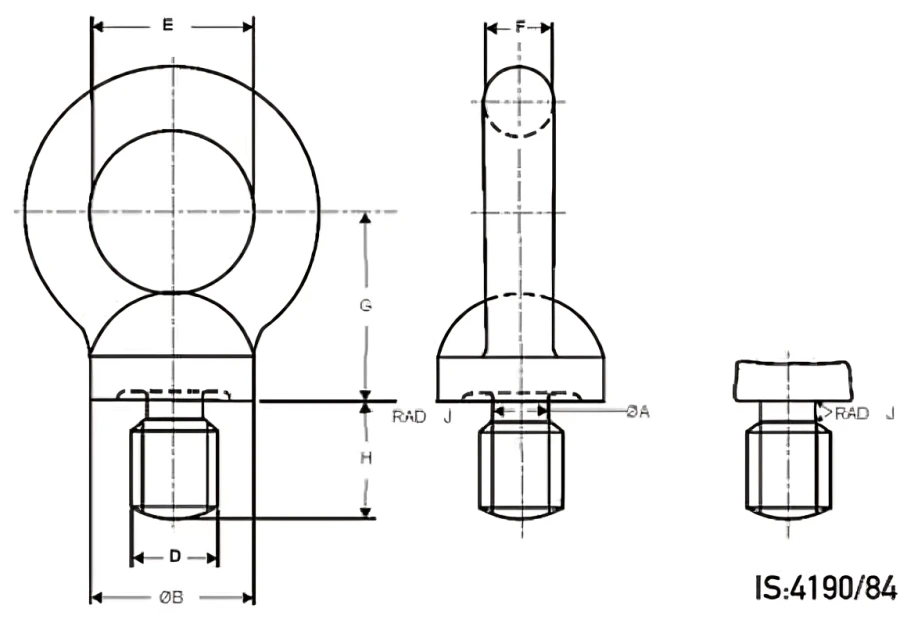

- Designed with a threaded shank, shoulder or collar, and a forged eye for secure attachment of hooks and lifting slings

- Precision threading allows easy and secure installation into pre-drilled holes or inserts

- Manufactured with defined load capacities and weight ratings for safe lifting and securing operations

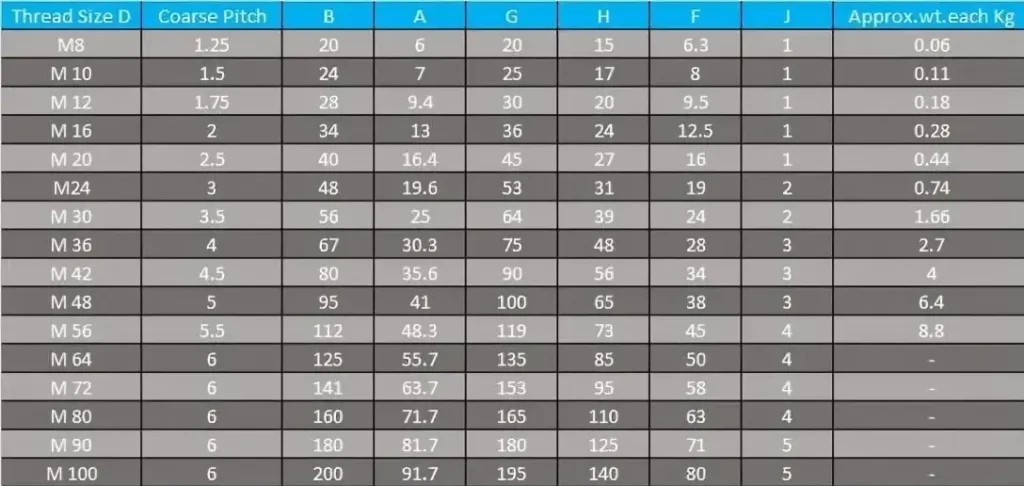

- Available in multiple sizes to suit different load-bearing requirements

- Versatile use in lifting heavy objects, suspending equipment, rigging, anchoring, and load securing

- Suitable for construction, manufacturing, marine, power, oil & gas, and material handling applications

- Manufactured in materials such as stainless steel, carbon steel, and galvanized steel

- Optional coatings and finishes provide enhanced corrosion resistance and durability

- Can be installed using threaded holes, nuts and washers, or anchor and expansion inserts

- Require proper installation, correct lifting techniques, and regular inspection for safety

SVIBO Industries offers high-quality eye bolts engineered for strength, reliability, and long service life across diverse applications. It is essential to use eye bolts within their specified load capacities, follow proper installation procedures, and adhere to safety guidelines to ensure safe and reliable operation. Consulting a qualified engineer or rigging professional can provide additional guidance on selecting and using eye bolts appropriately.

SVIBO Industries is a reliable Eye Bolt Manufacturer in India and trusted Eye Bolt Supplier in India, offering high-quality, durable eye bolts for lifting, rigging, and industrial applications.

Installation & Safe Usage Guidelines

- Correct Embedding : Always screw full thread engagement, or use appropriate nuts/washer assembly for secure anchoring.

- Loading Angles : 1. Use shoulder eye bolts for angular loads up to 45°, avoiding bending failure under strain.2. Opt for plain eye bolts only for vertical loads.

- Torque & Seating : Tighten threads to manufacturer specs and ensure bolt shoulders are flush against mounting surface for proper load transfer..

- Regular Inspection : Before use, check for:1. Thread damage2. Elongation or deformation in the eye3. Rust or corrosion

- Avoid Misuse : Do not use eye bolts as swivel components or at sharp angles beyond design limits to prevent excessive wear or mechanical failure.

Maintenance & Inspection Protocol

- Monthly Visual Checks - Examine threads and eyes for damage or corrosion.

- Lubrication - Apply light oil to threads to prevent rust and minimize wear.

- Non-Destructive Testing (NDT) - Conduct NDT (e.g., dye-penetrant testing) periodically on lifting eye bolts to identify hidden cracks.

- Load Retesting - Re-validate working load limit on eye bolts returned to stock or used under extreme conditions.